Our Services

Creating Reliable Plastic Enclosures Through Smart Process

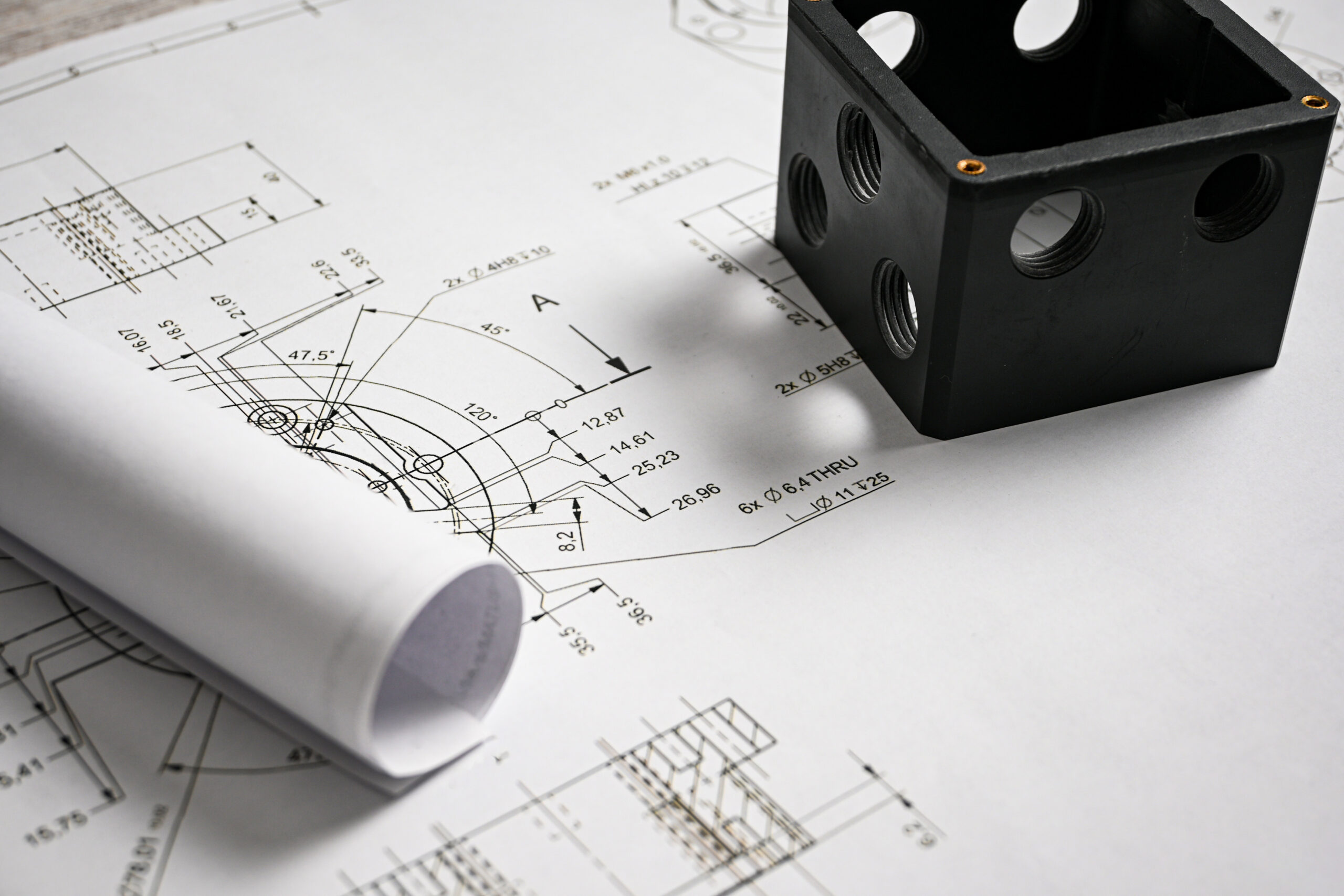

Our custom engineering services are built around one goal: getting your plastic enclosure from requirements to a production-ready, moldable design that passes IP/NEMA testing. We can support the entire enclosure development cycle—from early requirements and concepts through detailed design, simulation, and test-driven refinements—or step in to solve a specific enclosure or DFM problem.

Product Definition

Enclosure Requirements & Use Environment

Concept Design

Enclosure Concepts & DFM

Product Development

Enclosure Engineering & Design

Product Support

Provide Documentation & Support

Services to Fit Your Enclosure Design Needs

At Boah Engineering, our services are structured to support you wherever you are in the enclosure journey. Whether you’re defining a new IP-rated housing, trying to fix an existing design that’s causing test or tooling issues, or you’re a molder needing better customer-supplied CAD, we can engage at the right level.

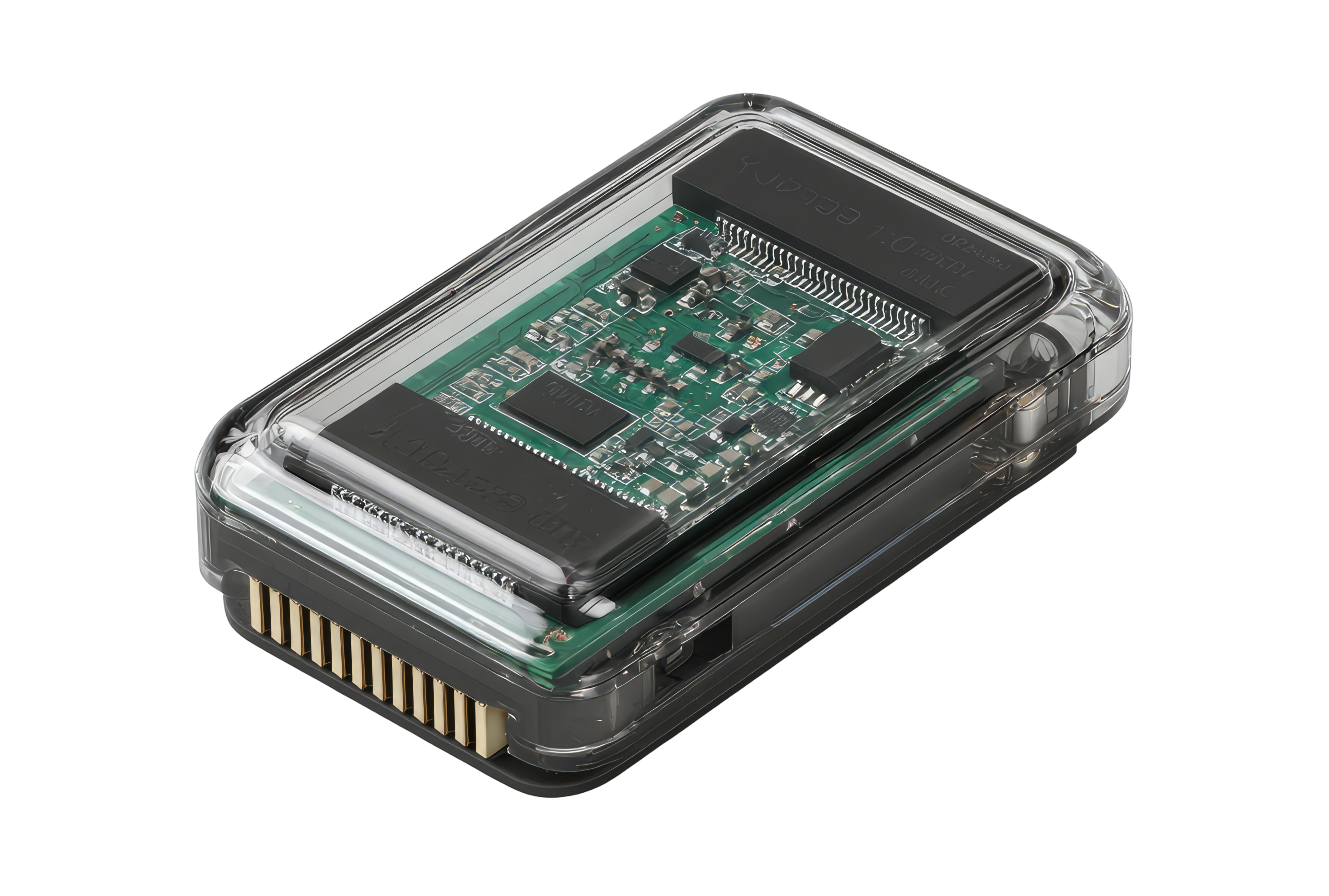

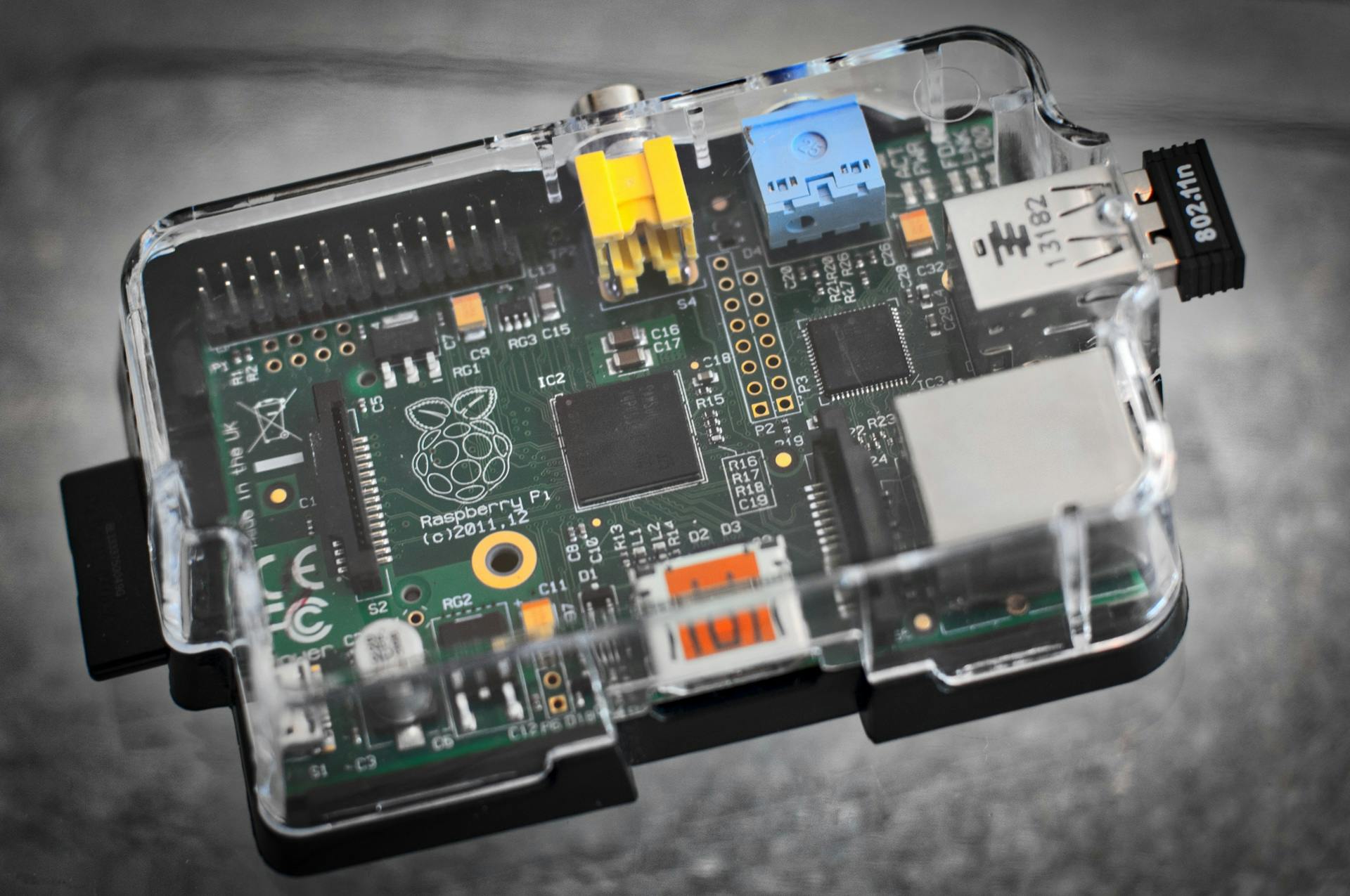

Our core focus is injection-molded plastic enclosures for electronics—offered as full front-end development or targeted a la carte services in design, simulation, DFM, and prototyping.

Enclosure Design & Engineering

Boah Engineering provides focused design and engineering services for injection-molded plastic enclosures and related components. We turn requirements and rough concepts into mold-ready housing designs for industrial, medical/wellness, and IoT electronics.

Capabilities:

- Plastic Enclosure CAD

- Design for Manufacturing & Assembly (DFM/DFA)

- IP-NEMA-oriented design

- Material and Sealing Selection for Use Case

- GD&T and Tolerance Analysis for Enclosure Fit & Sealing

- Reverse Engineering and Redesign of Existing Enclosures

- Simulation of Critical to Quality Features

- Cross Functional Collaboration

Enclosure Product Development

We plug into your internal teams to take ownership of the enclosure portion of your product development. Whether you’re launching a new device or upgrading an existing one, we focus on making sure the housing is engineered for performance, manufacturability, and test success.

What we deliver:

- Enclosure requirements and definition tied to product and test needs

- Concept generation and comparison of housing options

- Multi-disciplinary integration of PCB, batteries, displays, and connectors into the enclosure

- Prototypes and working enclosure models for fit, assembly, and basic environmental checks

- Support for product validation, design verification, and test-driven design changes focused on the housing

- Documentation for Manufacturing & Support

Rapid Enclosure Prototyping

Expertise

- Coordinate 3D Printing of Enclosure Components for Fit and Assembly Trials

- Coordinate CNC Machining of Prototype Enclosures

- Coordiante Prototype Tooling

- Prototype enclosure assembly and mechanical / environmental checks

Simulation & DFM for Enclosures

We leverage CAD and FEA to de-risk critical enclosure features before tooling. Targeted simulation—combined with plastics DFM—helps reduce the number of prototype loops and tooling changes required to achieve a robust housing.

Outsource enclosure and plastic design to augment your team’s capacity.

Expertise

- Structural studies on snaps, bosses, mounting tabs, and stiffening features

- Thermal studies related to enclosure wall design and internal heat sources

- Verification for design changes driven by test results

- Flow and filling considerations in collaboration with molders

Welcome to Boah Engineering

Product Development

[01]

- Lorem ipsum dolor sit amet, consectetur adipiscing elit

- Sed do eiusmod tempor incididunt ut labore et

- Ut enim ad minim veniam

- Quis nostrud exercitation ullamco laboris

Design

[02]

- Lorem ipsum dolor sit amet, consectetur adipiscing elit

- Sed do eiusmod tempor incididunt ut labore et

- Ut enim ad minim veniam

- Quis nostrud exercitation ullamco laboris

Simulation

[03]

- Lorem ipsum dolor sit amet, consectetur adipiscing elit

- Sed do eiusmod tempor incididunt ut labore et

- Ut enim ad minim veniam

- Quis nostrud exercitation ullamco laboris

Prototyping

[04]

- Lorem ipsum dolor sit amet, consectetur adipiscing elit

- Sed do eiusmod tempor incididunt ut labore et

- Ut enim ad minim veniam

- Quis nostrud exercitation ullamco laboris